close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2023-08-22 Origin: Site

When it comes to assessing the strength of scaffold netting, there are several important factors to consider. Scaffold netting is a vital component in ensuring safety on construction sites and other elevated work areas. It serves as a protective barrier, preventing objects from falling and providing a safe working environment for workers. To ensure the effectiveness and reliability of scaffold netting, the following factors should be taken into account.

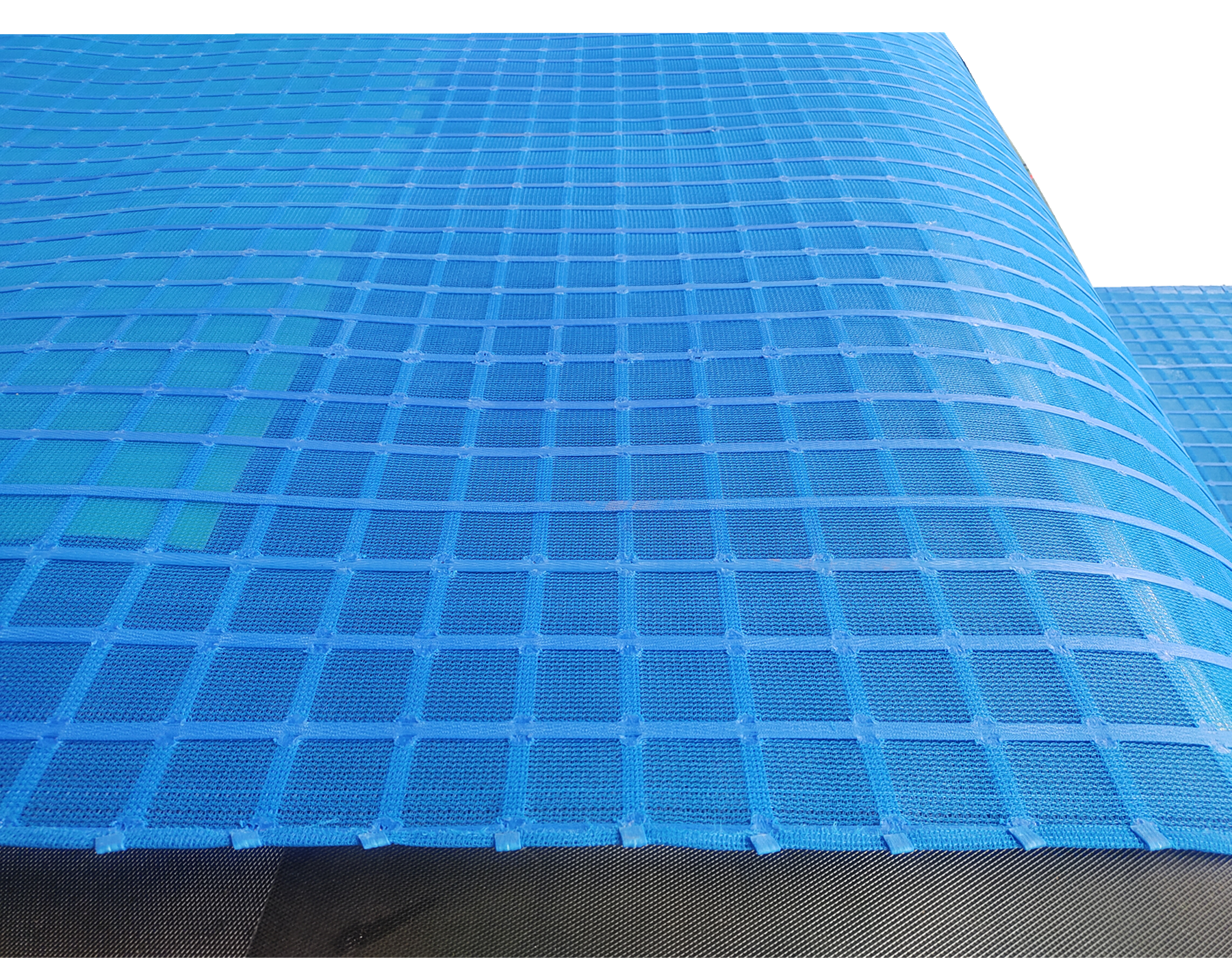

Firstly, the material used in the construction of scaffold netting plays a crucial role in determining its strength. High-quality materials such as polyethylene or nylon are commonly used due to their durability and resistance to tearing. These materials are also weather-resistant, ensuring that the netting remains strong and intact even in harsh conditions. It is important to choose scaffold netting made from reliable materials to ensure its strength and longevity.

Secondly, the mesh size of the scaffold netting is another factor to consider. The mesh size refers to the spacing between the individual strands of the netting. A smaller mesh size provides better protection by preventing smaller objects from passing through. This is particularly important when working in areas where there is a risk of small debris falling. By choosing scaffold netting with an appropriate mesh size, the risk of accidents and injuries can be minimized.

Additionally, the weight capacity of the scaffold netting should be evaluated. Different types of work require varying levels of load-bearing capacity. It is crucial to assess the weight that the netting needs to support and ensure that it meets the required standards. By considering the weight capacity of the scaffold netting, the risk of overloading and structural failure can be minimized.

Furthermore, the installation process and maintenance of the scaffold netting should be taken into account. Proper installation is essential to ensure that the netting is securely attached and can effectively serve its purpose. Regular inspection and maintenance are also necessary to identify any signs of wear or damage and to address them promptly. By following the recommended installation and maintenance procedures, the strength and reliability of the scaffold netting can be maintained.

Scaffold netting is an essential tool in the construction industry, offering a wide range of benefits for both workers and the overall project. One of the primary advantages of using strong scaffold netting is its ability to provide a safe working environment. With construction sites often being high-risk areas, it is crucial to have measures in place to protect workers from potential hazards. Scaffold netting acts as a protective barrier, preventing accidents such as falls and debris from causing harm.

In addition to safety, scaffold netting also offers considerable cost savings. By using netting, construction companies can significantly reduce the risk of materials and tools falling from heights, which not only puts workers at risk but also leads to costly damage and delays. The netting acts as a catchment system, preventing objects from falling to the ground and potentially causing injuries or property damage. This not only saves money on repairs and insurance claims but also ensures that projects are completed on time and within budget.

Another advantage of using scaffold netting is its versatility. It can be easily installed and adjusted to fit various scaffold structures, making it suitable for different types of construction projects. Whether it's a high-rise building, a bridge, or a simple renovation, scaffold netting provides a flexible solution that can be tailored to meet specific requirements. This adaptability not only enhances safety but also improves overall efficiency and productivity on the job site.

Furthermore, scaffold netting also contributes to environmental sustainability. By preventing debris and materials from falling, it reduces the amount of waste generated during construction. This not only minimizes the environmental impact but also promotes a cleaner and more organized work environment. Additionally, scaffold netting can be reused multiple times, further reducing waste and conserving resources. This commitment to sustainability aligns with the growing awareness and importance of eco-friendly practices in the construction industry.

The article emphasizes the importance of assessing the strength of scaffold netting in construction sites and elevated work areas. Factors such as the material used, mesh size, weight capacity, installation, and maintenance should be carefully evaluated to ensure worker safety and well-being. Scaffold netting plays a critical role in preventing accidents and injuries, and by considering these factors, its strength can be optimized. Additionally, the article highlights the numerous benefits of using strong scaffold netting, including worker safety, cost reduction, improved efficiency, and environmental sustainability. Investing in high-quality netting and incorporating it into construction practices can create a safer, more efficient, and environmentally conscious work environment. The article concludes by advising against overlooking the advantages of utilizing scaffold netting in construction projects.