close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2023-08-31 Origin: Site

Geogrids have become an essential component in infrastructure projects, providing stability and strength to various applications. But what exactly is a geogrid and how is it manufactured? In this article, we will delve into the intricacies of geogrids, exploring their manufacturing process, benefits, and applications.

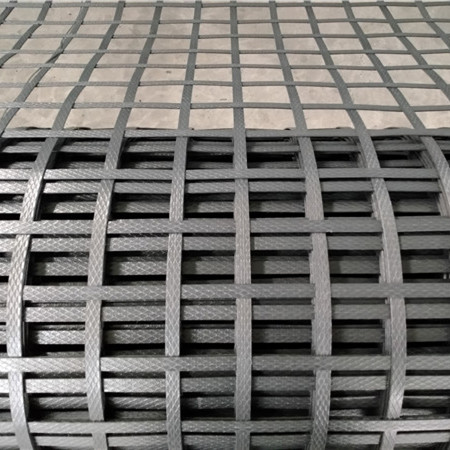

A geogrid is a type of geosynthetic material that is commonly used in civil engineering and construction projects. It is a flexible and durable grid-like structure made from polymers or other synthetic materials. Geogrids are designed to reinforce soil, aggregate, or other fill materials, providing them with increased stability and strength.

One of the main purposes of using a geogrid is to improve the load-bearing capacity of the soil. By placing the geogrid within the soil layers, it helps to distribute the load more evenly, reducing the risk of settlement or failure. This is particularly important in areas with weak or unstable soils, where the use of geogrids can significantly enhance the overall stability of the structure.

Geogrids are also effective in preventing the lateral spreading of soil or aggregate materials. They act as a barrier, restricting the movement of particles and preventing the loss of material due to erosion or displacement. This is particularly crucial in applications such as retaining walls, embankments, and slopes, where soil erosion can compromise the integrity of the structure.

Another advantage of using geogrids is their ability to enhance the performance of pavements and roadways. By incorporating geogrids into the pavement layers, it helps to distribute the traffic loads more effectively, reducing the stress on the underlying layers. This can result in improved pavement performance, increased lifespan, and reduced maintenance needs.

In addition to their technical benefits, geogrids are also environmentally friendly. They are made from recyclable materials and can be reused in other projects, reducing the overall environmental impact. Furthermore, the use of geogrids can help minimize the need for excavation and the amount of fill material required, resulting in less disruption to the surrounding environment.

Geogrid manufacturing is a complex process that involves several stages to produce a high-quality product. Geogrids are essential in civil engineering and construction projects as they provide reinforcement and stability to soil and pavement structures. Understanding the process of geogrid manufacturing is crucial for engineers and professionals in the industry.

The first step in geogrid manufacturing is the selection of raw materials. High-density polyethylene (HDPE) or polypropylene (PP) are commonly used as the base material for geogrids. These materials are chosen for their excellent tensile strength, durability, and resistance to environmental factors.

Once the raw materials are selected, they undergo a melting process. The HDPE or PP pellets are heated to their melting point and then extruded through a die to form a continuous sheet. This sheet is then stretched in both the machine and transverse directions to orient the molecules and improve the geogrid's tensile properties. The stretching process also creates the characteristic grid-like structure of the geogrid.

After the stretching process, the geogrid undergoes a process called coating. A thin layer of polymer is applied to the geogrid to enhance its bonding properties and protect it from UV radiation and chemical degradation. The coating also provides additional strength and stability to the geogrid, making it suitable for various applications.

The next step in geogrid manufacturing is the heat-setting process. The coated geogrid is subjected to high temperatures to ensure that the polymer coating fully adheres to the base material. This heat treatment also helps to stabilize the geogrid's structure and improve its dimensional stability.

Quality control is an integral part of the geogrid manufacturing process. The geogrids undergo rigorous testing to ensure they meet the required specifications and standards. These tests include tensile strength, elongation, and aperture size measurements. Only geogrids that pass these tests are considered suitable for use in construction projects.

Geogrids are a revolutionary solution that has gained popularity in recent years due to their numerous benefits and wide range of applications. These synthetic materials, often made from polymers such as polyester or polypropylene, are designed to improve the stability and strength of soil and other materials in geotechnical engineering projects.

One of the key benefits of geogrids is their ability to enhance soil reinforcement. By distributing the load evenly across a larger area, geogrids can significantly increase the bearing capacity of the soil. This is particularly useful in construction projects where the soil may be weak or unstable, as geogrids can help prevent settlement and improve overall stability.

Another advantage of geogrids is their ability to control erosion. By providing a barrier that prevents soil particles from being washed away by water or wind, geogrids can effectively protect slopes, embankments, and other vulnerable areas from erosion. This is crucial in areas prone to heavy rainfall or strong winds, as erosion can lead to costly damage and even endanger human life.

Geogrids also play a vital role in the reinforcement of retaining walls and steep slopes. By providing additional support and preventing soil movement, geogrids can help prevent the collapse of these structures. This is particularly important in areas with uneven terrain or high groundwater levels, where the stability of retaining walls and slopes may be compromised.

In addition to their benefits in geotechnical engineering, geogrids also have a wide range of applications in other industries. For example, they are commonly used in road construction to improve the performance and lifespan of pavements. By reducing the stresses on the pavement layers and preventing cracking and rutting, geogrids can significantly extend the life of roads and reduce the need for costly repairs.

Furthermore, geogrids are also used in the agricultural sector to improve soil quality and increase crop yields. By enhancing soil stability and preventing erosion, geogrids can help farmers protect their land and optimize their agricultural practices. This is particularly relevant in areas with challenging soil conditions or steep slopes, where erosion and soil degradation can have a significant impact on crop productivity.

Geogrids play a crucial role in the field of civil engineering and construction. These synthetic materials, typically made from polymers such as polyester or polypropylene, are designed to provide reinforcement and stability to soil structures. They are commonly used in various applications, including roadway construction, retaining walls, and slope stabilization.

One key aspect of geogrids is their maintenance and longevity. Proper maintenance is essential to ensure the long-term performance and durability of these materials. Regular inspection and monitoring are necessary to detect any signs of damage or deterioration. This proactive approach allows for timely repairs or replacements, minimizing potential risks and optimizing the lifespan of geogrids.

Maintenance activities for geogrids may include removing debris, such as leaves and sediment, from the surface. This prevents clogging and maintains the functionality of the geogrids. Additionally, regular cleaning and inspection of the soil surrounding the geogrids are crucial to prevent the accumulation of harmful substances or vegetation growth, which can weaken the structure over time.

To enhance the longevity of geogrids, it is important to ensure proper installation. Following manufacturer guidelines and industry best practices is vital to maximize the effectiveness of these materials. This includes proper soil preparation, accurate placement, and adequate compaction. By adhering to these guidelines, the geogrids can withstand heavy loads, resist deformation, and maintain their integrity for extended periods.

Furthermore, geogrids can benefit from routine maintenance techniques such as geosynthetics testing. This involves conducting laboratory tests to assess the strength and performance characteristics of the geogrids. By evaluating these properties, engineers and contractors can identify potential weaknesses or areas of improvement, allowing for targeted maintenance and ensuring the long-term functionality of the geogrids.

Geogrids are a versatile and valuable geosynthetic material that plays a crucial role in civil engineering and construction projects. They reinforce soil, prevent erosion, and enhance pavement performance. Geogrid manufacturing involves careful selection of raw materials, melting and extrusion, stretching, coating, heat-setting, and quality control. Geogrids provide reinforcement and stability to soil and pavement structures. They offer a wide range of benefits and applications in various industries, including soil reinforcement, erosion control, and improving infrastructure. Regular inspection, cleaning, and monitoring are necessary for the maintenance and longevity of geogrids. Proper installation and adherence to manufacturer guidelines contribute to their durability and performance. Geogrids are a smart choice for engineers and contractors looking to improve the stability and sustainability of their projects.