close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

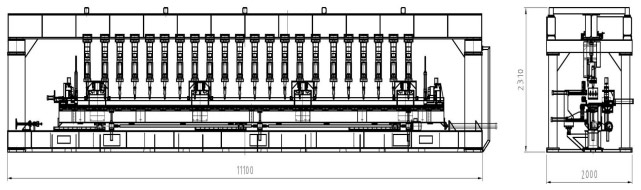

Automatic Ultrasonic Geocell Welding Machine

DKM Geocell Ultrasonic Welding Machine

1. Main technical parameters:

1.Ultrasonic transducer adopts Germany piezoelectric ceramic power: 2800w Frequency:15Khz.

2.Ultrasonic horn adopts imported aluminum from USA. The horn length is 320mm. The quality warranty is 6 months after the buyer received it.

3.all pneumatic element are from AirTAC.

4.The highest working power of machine is 18Kw, the welding distance is 200mm-800mm and it is adjustable.

5.Machine dimension:11800mm×2000mm×2500mm.

2. Technical requirement:

1.The maximum deflection of the gantry beam is below 5mm.Upper beam is 400H steel and 300*150 quarter bend,it can ensure the machines stability and rigidity.there have gear racks on the beam for the sake of adjusting and positioning.

2.Each ultrasonic welding machine can be adjusted simultaneously and can be controlled separately (such as repair welding), and each welding head must be equipped with an alarm device. The sound head parameters can be set synchronously. The sound head and the transducer should be connected well to improve the efficiency of the transducer.

3.The needle shape of the ultrasonic horn should meet the requirements of the seam peel strength of the weld and reach the best, (it can also be customized according to the size provided by the buyer).

4.The gas path of the equipment is increased by 150mm seamless pipe for gas storage to ensure stable output of storage pressure.

5.The whole production line could be operated flexibly, the automatic program controlling or manual welding mode works smoothly and without block. The front and rear bottom die strips of the welding equipment are on one side and are equipped with independent positioning slides.Bottom horn strip should be rigid enough,it can be positioning accurately .When changing the bottom horn strip,it should be convenient to use wrench to fasten.it can ensure the stability in working.

6.The section size of the welded sheet is 1mm~2mm thick.

7.Ultrasonic weld peeling strength: ≥1450N、1800N、2000N/100mm (in the height direction of the cell), except for the quality of the sheet.

8.Synchronous welding, welding a whole row with each tact 12s, to ensure that the strength of each welding spot is similar and qualified, and the welding time is adjustable.

10.Daily output (24h) 2500-8500 square meters. (Depending on skillful operation, plate width and welding distance)

11.The number of operators is 2 to 3 people.

12.Provide a backup device program.

13.Provide production line operation and maintenance instructions.

3. The specification of geocell:

1.Sheet width ≤300mm, cell height: 75、100、150、200mm、250mm、300mm.

2.Sheet length≤8500mm.

3.The length,pitch at 8500mm direction is adjustable.the minimum distance is 260mm.

Model | YH-9500 |

welding post quantity | 41units |

Output powder | 32KW |

Estimate size of the Equipment(L*W*H)/mm | 11800*2000*2500mm |

Welding machine working plate Width | 9.5m |

Weight | 13.5T |

Rated In Voltage | AC380V & 50HZ |

Air Pressure | 0.6-0.8MPa |

Welding distance scope | 200-800mm |

Geogrid sheet width | 50mm-300mm Adjustable |

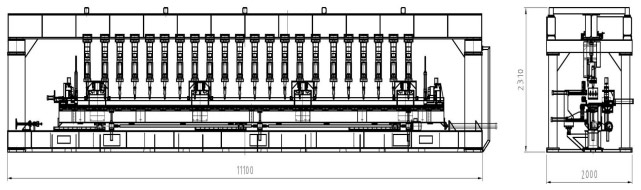

DKM Geocell Ultrasonic Welding Machine

1. Main technical parameters:

1.Ultrasonic transducer adopts Germany piezoelectric ceramic power: 2800w Frequency:15Khz.

2.Ultrasonic horn adopts imported aluminum from USA. The horn length is 320mm. The quality warranty is 6 months after the buyer received it.

3.all pneumatic element are from AirTAC.

4.The highest working power of machine is 18Kw, the welding distance is 200mm-800mm and it is adjustable.

5.Machine dimension:11800mm×2000mm×2500mm.

2. Technical requirement:

1.The maximum deflection of the gantry beam is below 5mm.Upper beam is 400H steel and 300*150 quarter bend,it can ensure the machines stability and rigidity.there have gear racks on the beam for the sake of adjusting and positioning.

2.Each ultrasonic welding machine can be adjusted simultaneously and can be controlled separately (such as repair welding), and each welding head must be equipped with an alarm device. The sound head parameters can be set synchronously. The sound head and the transducer should be connected well to improve the efficiency of the transducer.

3.The needle shape of the ultrasonic horn should meet the requirements of the seam peel strength of the weld and reach the best, (it can also be customized according to the size provided by the buyer).

4.The gas path of the equipment is increased by 150mm seamless pipe for gas storage to ensure stable output of storage pressure.

5.The whole production line could be operated flexibly, the automatic program controlling or manual welding mode works smoothly and without block. The front and rear bottom die strips of the welding equipment are on one side and are equipped with independent positioning slides.Bottom horn strip should be rigid enough,it can be positioning accurately .When changing the bottom horn strip,it should be convenient to use wrench to fasten.it can ensure the stability in working.

6.The section size of the welded sheet is 1mm~2mm thick.

7.Ultrasonic weld peeling strength: ≥1450N、1800N、2000N/100mm (in the height direction of the cell), except for the quality of the sheet.

8.Synchronous welding, welding a whole row with each tact 12s, to ensure that the strength of each welding spot is similar and qualified, and the welding time is adjustable.

10.Daily output (24h) 2500-8500 square meters. (Depending on skillful operation, plate width and welding distance)

11.The number of operators is 2 to 3 people.

12.Provide a backup device program.

13.Provide production line operation and maintenance instructions.

3. The specification of geocell:

1.Sheet width ≤300mm, cell height: 75、100、150、200mm、250mm、300mm.

2.Sheet length≤8500mm.

3.The length,pitch at 8500mm direction is adjustable.the minimum distance is 260mm.

Model | YH-9500 |

welding post quantity | 41units |

Output powder | 32KW |

Estimate size of the Equipment(L*W*H)/mm | 11800*2000*2500mm |

Welding machine working plate Width | 9.5m |

Weight | 13.5T |

Rated In Voltage | AC380V & 50HZ |

Air Pressure | 0.6-0.8MPa |

Welding distance scope | 200-800mm |

Geogrid sheet width | 50mm-300mm Adjustable |