close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

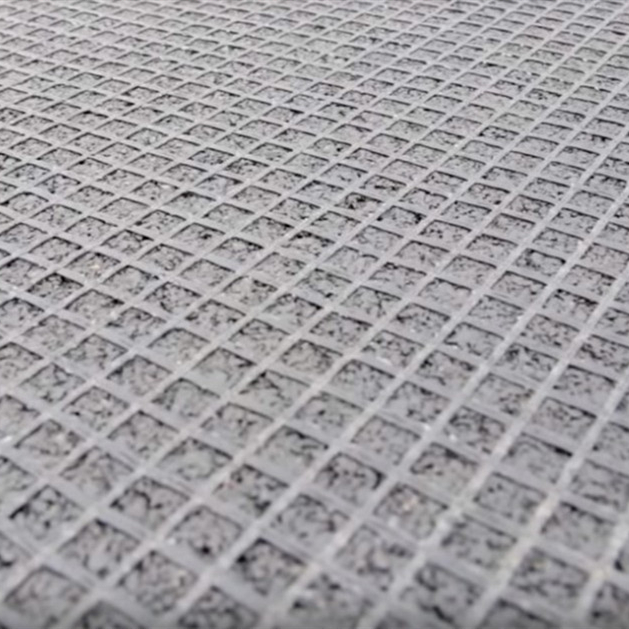

Pavement Biaxial Fiberglass Geogrid is a ploymer coated fiberglass geogrid, helps reinforce the asphalt on flexible pavement to enhance pavement life and performance,expand pavement life up to 3 times by reducing reflective cracking.

Pavement Biaxial Fiberglass Geogrid, the perfect solution for reinforcing old asphalt concrete road surfaces and enhancing road expansion and improvement projects.

Designed with utmost precision and quality, our geogrid is specifically engineered to provide exceptional reinforcement to aging road surfaces. Its biaxial construction offers superior strength and durability, ensuring long-lasting performance even under heavy traffic loads.

With its advanced composition, our geogrid effectively distributes stress and prevents cracking, rutting, and other forms of pavement distress. By reinforcing the existing asphalt concrete, it significantly extends the lifespan of the road, reducing maintenance costs and enhancing overall road safety.

· Placed underneath the bitumen wearing course in roads, highways and airports to control reflective cracking.

· New build and repairing damaged tarmacked surfaces on roads, motorways, car parks, access roads and airports.

· High traffic pavement to control of rutting.

Parameter Data of DKM Fiberglass Geogrid

TESTED PROPERTY | TEST METHOD | UNIT | EGA30/30 | EGA50/50 | EGA70/70 | EGA80/80 | EGA100/100 | EGA150/150 | EGA160/160 |

Ultimate Tensile Strength | ASTM D 6337 | kN/m | 30 | 50 | 70 | 80 | 100 | 150 | 160 |

Shrinkage Properties | Internal Test Method | % | Less than 0.5% at 200˚C afte 15 minutes | ||||||

Strain at Ultimate(2) | ASTM D 6637 | % | <3 | ||||||

Grid Material | Fiberglass Grid | ||||||||

Coating | Polymeric with pressure sensitive self-adhesive backing | ||||||||

Melting Point Coating | ASTM D 276 | ˚C | >350 | ||||||

Melting Point Glass | ASTM C 338 | ˚C | >820 | ||||||

Aperture Size (centre to centre of strand) | Nominal | mm | 25.4*25.4mm | ||||||

Roll Width | m | 1.5m/2m/2.5m/3m | |||||||

Roll Length | m | 100m | |||||||

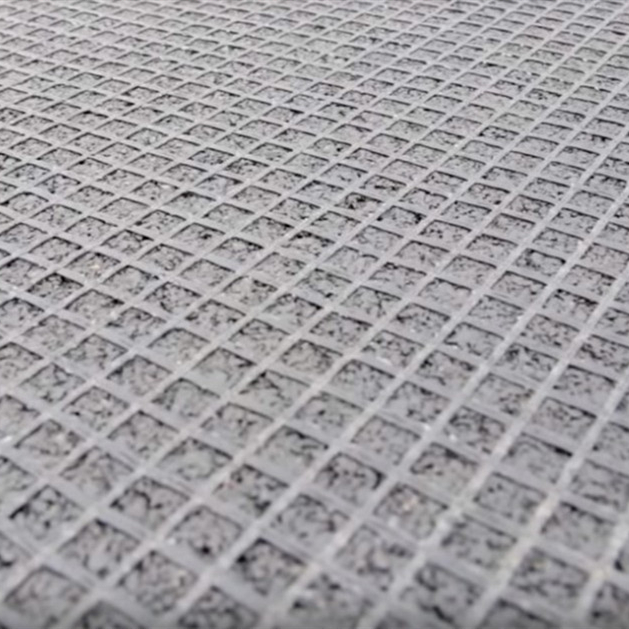

Pavement Biaxial Fiberglass Geogrid is a ploymer coated fiberglass geogrid, helps reinforce the asphalt on flexible pavement to enhance pavement life and performance,expand pavement life up to 3 times by reducing reflective cracking.

Pavement Biaxial Fiberglass Geogrid, the perfect solution for reinforcing old asphalt concrete road surfaces and enhancing road expansion and improvement projects.

Designed with utmost precision and quality, our geogrid is specifically engineered to provide exceptional reinforcement to aging road surfaces. Its biaxial construction offers superior strength and durability, ensuring long-lasting performance even under heavy traffic loads.

With its advanced composition, our geogrid effectively distributes stress and prevents cracking, rutting, and other forms of pavement distress. By reinforcing the existing asphalt concrete, it significantly extends the lifespan of the road, reducing maintenance costs and enhancing overall road safety.

· Placed underneath the bitumen wearing course in roads, highways and airports to control reflective cracking.

· New build and repairing damaged tarmacked surfaces on roads, motorways, car parks, access roads and airports.

· High traffic pavement to control of rutting.

Parameter Data of DKM Fiberglass Geogrid

TESTED PROPERTY | TEST METHOD | UNIT | EGA30/30 | EGA50/50 | EGA70/70 | EGA80/80 | EGA100/100 | EGA150/150 | EGA160/160 |

Ultimate Tensile Strength | ASTM D 6337 | kN/m | 30 | 50 | 70 | 80 | 100 | 150 | 160 |

Shrinkage Properties | Internal Test Method | % | Less than 0.5% at 200˚C afte 15 minutes | ||||||

Strain at Ultimate(2) | ASTM D 6637 | % | <3 | ||||||

Grid Material | Fiberglass Grid | ||||||||

Coating | Polymeric with pressure sensitive self-adhesive backing | ||||||||

Melting Point Coating | ASTM D 276 | ˚C | >350 | ||||||

Melting Point Glass | ASTM C 338 | ˚C | >820 | ||||||

Aperture Size (centre to centre of strand) | Nominal | mm | 25.4*25.4mm | ||||||

Roll Width | m | 1.5m/2m/2.5m/3m | |||||||

Roll Length | m | 100m | |||||||