close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

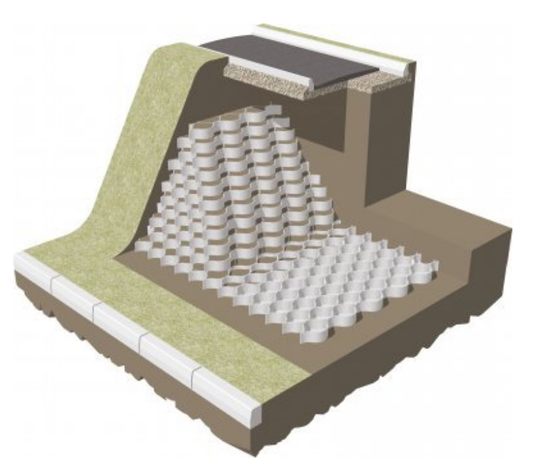

Geocell Retainning Wall System

Geocell Retainning Wall System is a flexible 3D honeycomb structures manufactured from HDPE(High Density Polyethylene ) or P.C.A sheets which welded together by ultrasonic technique. The Geocell widely use for Green and retaining wall reinforcement,Channel and Slope erosion control, Soil stabilization, Load support for drive way and parking lot,etc.

Features:

•Flexible, light weight, chemical stability, anti-aging and anti-acid/alkali corrosion.

•Expanded Size is adjustable, the cell height also can meet different projects request.

•Excellent rigidity and toughness property, high load strength and anti-erosion ability.

•Premium tensile strength and wide environmental adaptable.

Application:

•Load supporting for roadbed of drive way and railway.

•Bearing the dam and retaining wall’s pressure .

•Protect the slope from landslide and mudslide.

•Erosion control for channel from water flowing.

•Alao widely used for independent wall, wharf and breakwater projects, etc.

Property | Value | Test Method | ||

Base Material | ||||

Material Composition | Virgin Polyethylene with Density of 0.935-0.965g/cm3 | ASTM D1505 | ||

Color | Black/Gray/Green | N/A | ||

Strip Properties | ||||

Sheet Thickness | After Textured:≥1.45mm | ASTM D5199 | ||

Cell&Seam Properties | ||||

Cell Details | Welding distance (mm) | Dimension of per cell after expanded(±3%) | Expanded Panel size(Customization) | |

Length(mm) | Width(mm) | |||

GC-330 | 330 | 249 | 215 | 4.5m x 5.6m |

GC-356 | 356 | 268 | 231 | 5.1m x 5.9m |

GC-445 | 445 | 335 | 290 | 4.9m x7.1m |

GC-660 | 660 | 486 | 420 | 5.0m x 9.5m |

GC-712 | 712 | 528 | 455 | 5.1m x 11.7m |

Cell depths(±2%) | 50mm,100mm,150mm,200mm | |||

Welding Seam Peel Strength(±3%) | Can customized producing according the project condition. | |||

10.0KN/m | ISO 10319 | |||

14.2KN/m | ||||

16.0KN/m | ||||

18.0KN/m | ||||

Geocell sheet Tensile Strength(±5%) | Non-perforated: >20kn/m Perforated:> 10kn/m | ISO 10319 | ||

Oxidative Induction Time (OIT) (±5%) | ≥ 20 Minutes or 100 Minutes | ASTM D5885(@ 200℃)Test by GRI GM13Testing per GRI GM13 | ||

Plant Workshop

Storage

Delivery

Certificates

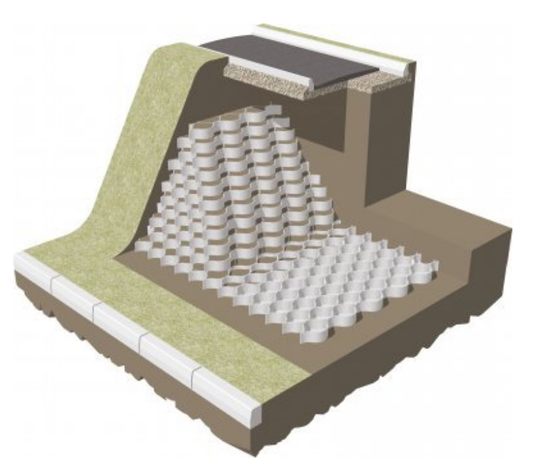

Geocell Retainning Wall System is a flexible 3D honeycomb structures manufactured from HDPE(High Density Polyethylene ) or P.C.A sheets which welded together by ultrasonic technique. The Geocell widely use for Green and retaining wall reinforcement,Channel and Slope erosion control, Soil stabilization, Load support for drive way and parking lot,etc.

Features:

•Flexible, light weight, chemical stability, anti-aging and anti-acid/alkali corrosion.

•Expanded Size is adjustable, the cell height also can meet different projects request.

•Excellent rigidity and toughness property, high load strength and anti-erosion ability.

•Premium tensile strength and wide environmental adaptable.

Application:

•Load supporting for roadbed of drive way and railway.

•Bearing the dam and retaining wall’s pressure .

•Protect the slope from landslide and mudslide.

•Erosion control for channel from water flowing.

•Alao widely used for independent wall, wharf and breakwater projects, etc.

Property | Value | Test Method | ||

Base Material | ||||

Material Composition | Virgin Polyethylene with Density of 0.935-0.965g/cm3 | ASTM D1505 | ||

Color | Black/Gray/Green | N/A | ||

Strip Properties | ||||

Sheet Thickness | After Textured:≥1.45mm | ASTM D5199 | ||

Cell&Seam Properties | ||||

Cell Details | Welding distance (mm) | Dimension of per cell after expanded(±3%) | Expanded Panel size(Customization) | |

Length(mm) | Width(mm) | |||

GC-330 | 330 | 249 | 215 | 4.5m x 5.6m |

GC-356 | 356 | 268 | 231 | 5.1m x 5.9m |

GC-445 | 445 | 335 | 290 | 4.9m x7.1m |

GC-660 | 660 | 486 | 420 | 5.0m x 9.5m |

GC-712 | 712 | 528 | 455 | 5.1m x 11.7m |

Cell depths(±2%) | 50mm,100mm,150mm,200mm | |||

Welding Seam Peel Strength(±3%) | Can customized producing according the project condition. | |||

10.0KN/m | ISO 10319 | |||

14.2KN/m | ||||

16.0KN/m | ||||

18.0KN/m | ||||

Geocell sheet Tensile Strength(±5%) | Non-perforated: >20kn/m Perforated:> 10kn/m | ISO 10319 | ||

Oxidative Induction Time (OIT) (±5%) | ≥ 20 Minutes or 100 Minutes | ASTM D5885(@ 200℃)Test by GRI GM13Testing per GRI GM13 | ||

Plant Workshop

Storage

Delivery

Certificates