close

Choose Your Site

Global

Social Media

| Color: | |

|---|---|

| Cell Height: | |

| Cell sheet Tensile Strength: | |

| Material: | |

| Availability: | |

| Quantity: | |

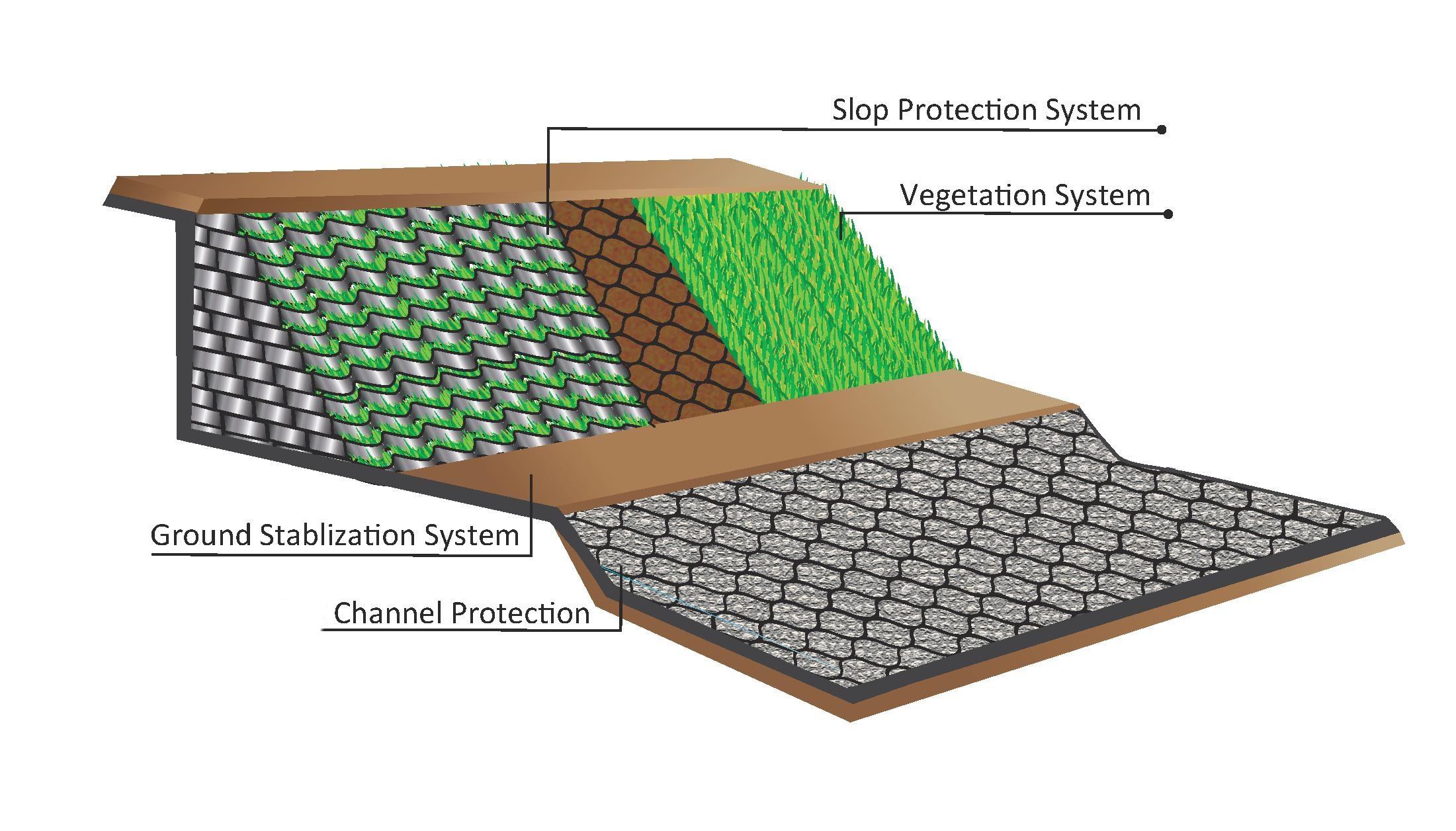

Geocell Slope & Channel Protection System

Plastic Geocell Material for Slope Erosion Control & Stabilization is a cellular confinement system manufactured from HDPE(High Density Polyethylene ) or P.C.A sheets which welded together by ultrasonic technique. It utilised enhance slope protection by stabilising the soil and steep slopes for earth retention in construction sites and widely use for Channel and slope erosion control, Green and retaining wall reinforcement, Soil stabilization, Load support for drive way and parking lot,etc.

One of the standout features of Plastic Geocell Material for Slope Erosion Control & Stabilization System is its adjustable expanded size. This unique characteristic allows for customization, enabling you to achieve the desired dimensions for your specific application. With this adaptability, you can seamlessly integrate our system into your project, regardless of its scale or complexity.

In addition to its flexibility and adjustability, Plastic Geocell Material for Slope Erosion Control & Stabilization System boasts high load strength and exceptional anti-erosion ability. This ensures that your project remains stable and secure, even in challenging environmental conditions. Count on our product to provide the necessary support and protection, safeguarding your investment for years to come.

Choose our Plastic Geocell Material for Slope Erosion Control & Stabilization System for a professional solution

Property | Value | Test Method | ||

Base Material | ||||

Material Composition | Virgin Polyethylene with Density of 0.935-0.965g/cm3 | ASTM D1505 | ||

Color | Black/Gray/Green | N/A | ||

Strip Properties | ||||

Sheet Thickness | After Textured:≥1.45mm | ASTM D5199 | ||

Cell&Seam Properties | ||||

Cell Details | Welding distance (mm) | Dimension of per cell after expanded(±3%) | Expanded Panel size(Customization) | |

Length(mm) | Width(mm) | |||

GC-330 | 330 | 249 | 215 | 4.5m x 5.6m |

GC-356 | 356 | 268 | 231 | 5.1m x 5.9m |

GC-445 | 445 | 335 | 290 | 4.9m x7.1m |

GC-660 | 660 | 486 | 420 | 5.0m x 9.5m |

GC-712 | 712 | 528 | 455 | 5.1m x 11.7m |

Cell depths(±2%) | 50mm,100mm,150mm,200mm | |||

Welding Seam Peel Strength(±3%) | Can customized producing according the project condition. | |||

10.0KN/m | ISO 10319 | |||

14.2KN/m | ||||

16.0KN/m | ||||

18.0KN/m | ||||

Geocell sheet Tensile Strength(±5%) | Non-perforated: >20kn/m Perforated:> 10kn/m | ISO 10319 | ||

Oxidative Induction Time (OIT) (±5%) | ≥ 20 Minutes or 100 Minutes | ASTM D5885(@ 200℃)Test by GRI GM13Testing per GRI GM13 | ||

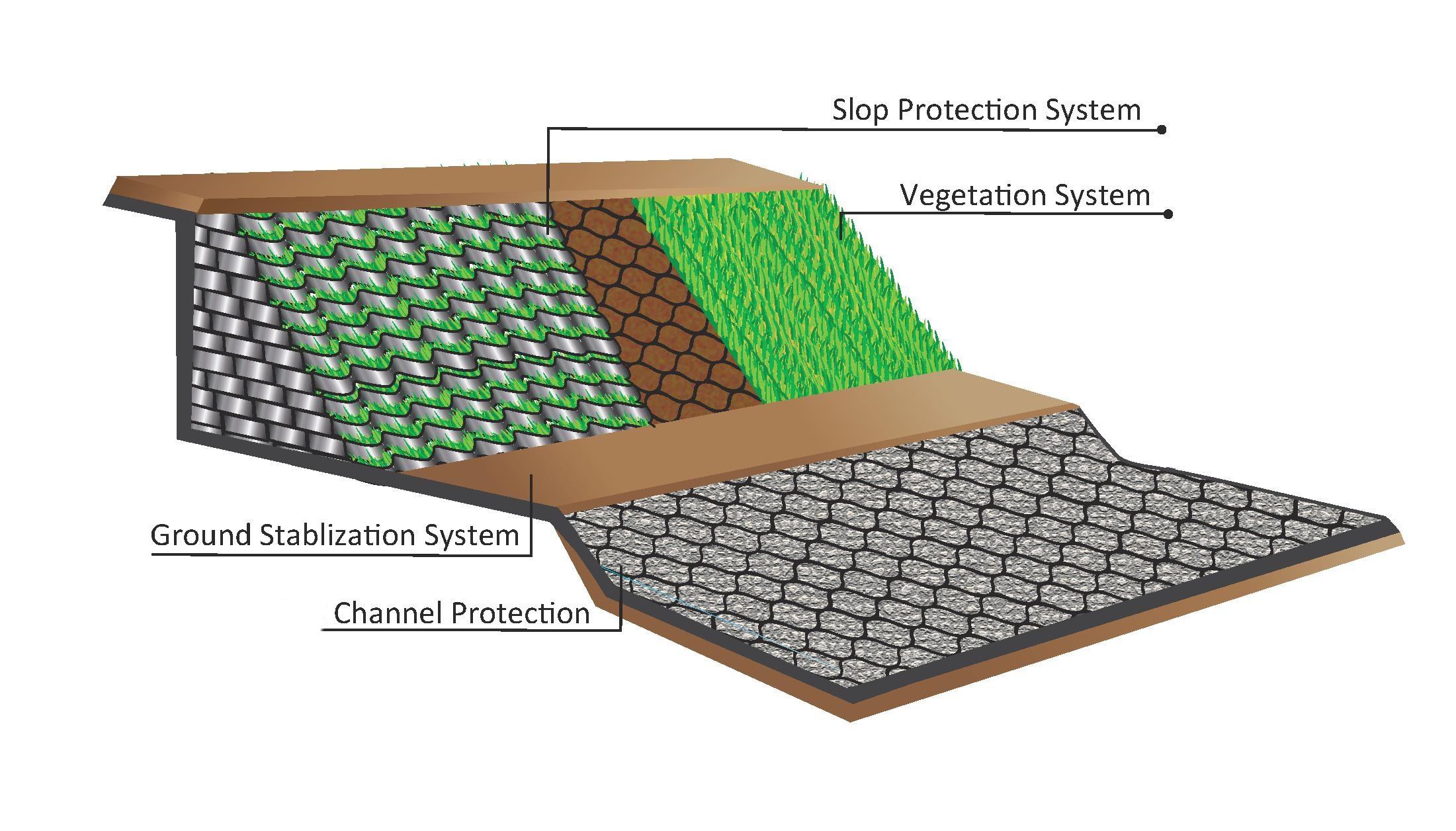

Plastic Geocell Material for Slope Erosion Control & Stabilization is a cellular confinement system manufactured from HDPE(High Density Polyethylene ) or P.C.A sheets which welded together by ultrasonic technique. It utilised enhance slope protection by stabilising the soil and steep slopes for earth retention in construction sites and widely use for Channel and slope erosion control, Green and retaining wall reinforcement, Soil stabilization, Load support for drive way and parking lot,etc.

One of the standout features of Plastic Geocell Material for Slope Erosion Control & Stabilization System is its adjustable expanded size. This unique characteristic allows for customization, enabling you to achieve the desired dimensions for your specific application. With this adaptability, you can seamlessly integrate our system into your project, regardless of its scale or complexity.

In addition to its flexibility and adjustability, Plastic Geocell Material for Slope Erosion Control & Stabilization System boasts high load strength and exceptional anti-erosion ability. This ensures that your project remains stable and secure, even in challenging environmental conditions. Count on our product to provide the necessary support and protection, safeguarding your investment for years to come.

Choose our Plastic Geocell Material for Slope Erosion Control & Stabilization System for a professional solution

Property | Value | Test Method | ||

Base Material | ||||

Material Composition | Virgin Polyethylene with Density of 0.935-0.965g/cm3 | ASTM D1505 | ||

Color | Black/Gray/Green | N/A | ||

Strip Properties | ||||

Sheet Thickness | After Textured:≥1.45mm | ASTM D5199 | ||

Cell&Seam Properties | ||||

Cell Details | Welding distance (mm) | Dimension of per cell after expanded(±3%) | Expanded Panel size(Customization) | |

Length(mm) | Width(mm) | |||

GC-330 | 330 | 249 | 215 | 4.5m x 5.6m |

GC-356 | 356 | 268 | 231 | 5.1m x 5.9m |

GC-445 | 445 | 335 | 290 | 4.9m x7.1m |

GC-660 | 660 | 486 | 420 | 5.0m x 9.5m |

GC-712 | 712 | 528 | 455 | 5.1m x 11.7m |

Cell depths(±2%) | 50mm,100mm,150mm,200mm | |||

Welding Seam Peel Strength(±3%) | Can customized producing according the project condition. | |||

10.0KN/m | ISO 10319 | |||

14.2KN/m | ||||

16.0KN/m | ||||

18.0KN/m | ||||

Geocell sheet Tensile Strength(±5%) | Non-perforated: >20kn/m Perforated:> 10kn/m | ISO 10319 | ||

Oxidative Induction Time (OIT) (±5%) | ≥ 20 Minutes or 100 Minutes | ASTM D5885(@ 200℃)Test by GRI GM13Testing per GRI GM13 | ||