close

Choose Your Site

Global

Social Media

| Color: | |

|---|---|

| Tensile Strength: | |

| Roll Width: | |

| Roll Length: | |

| Availability: | |

| Quantity: | |

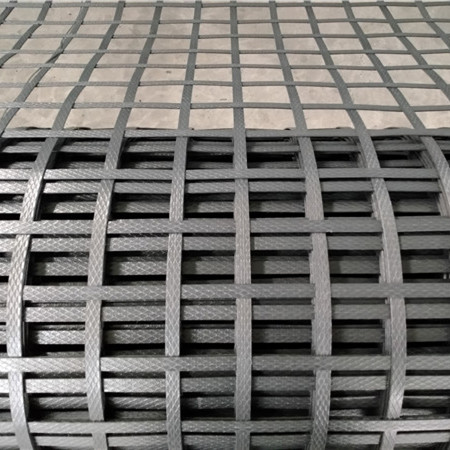

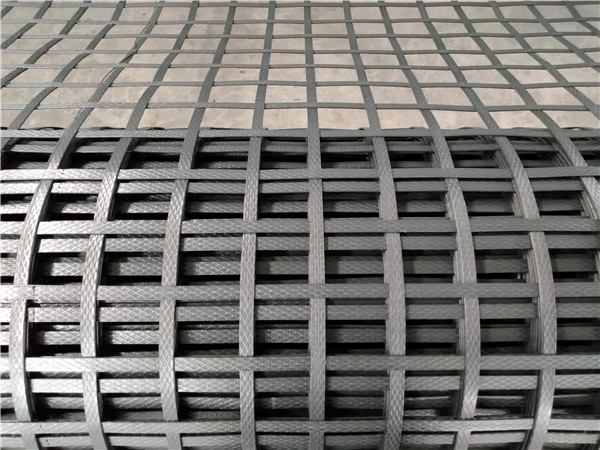

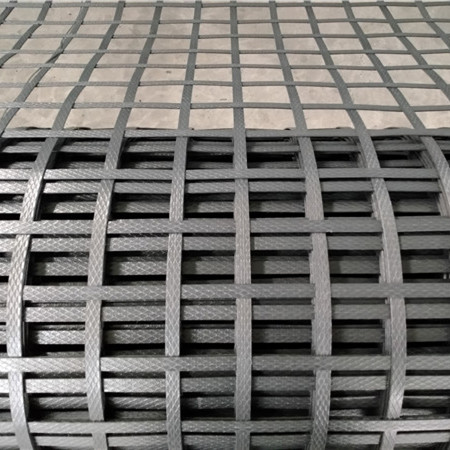

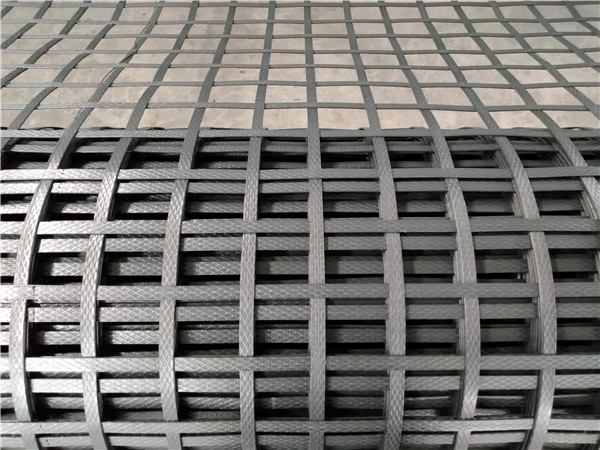

Plastic Ultrasonic Welded Geogrid

Plastic Ultrasonic Welded Geogrid are warp knitted polypropylene materials welded geogrid,it use polypropylene as raw materials,through extruding to be high tensile strength rib belt ,then the belts warp knitted and welded by Ultrasonic welding machine to make it have high tensile strength in CD/MD direction. This products mainly used for Soil stabilization,road sub-base reinforcement, aggregates confinement and improving the performance of road anti-pressure ability.

Features:

Plastic Ultrasonic Welded Geogrid is a high-quality and reliable solution for all your geotechnical needs. Designed with utmost precision and manufactured using state-of-the-art technology, this geogrid offers exceptional performance and durability.

With its high tensile strength, our Plastic Ultrasonic Welded Geogrid can withstand heavy loads and provide excellent reinforcement to the soil. This feature ensures enhanced load distribution, preventing soil erosion and offering long-lasting stability to your projects.

Installation of our geogrid is both convenient and easy, saving you valuable time and effort. Its innovative design allows for seamless integration into various applications, making it suitable for a wide range of projects. Whether you are working on road construction, embankments, or retaining walls, our geogrid guarantees efficient and hassle-free installation.

Technical Properties Specification | ||||||||

Spec Items | GSZ25 | GSZ30 | GSZ40 | GSZ60 | GSZ80 | GSZ100 | GSZ125 | |

Minimum Average Tensile Strength MD ≥(KN/m) | 25 | 30 | 40 | 60 | 80 | 100 | 125 | |

Minimum Average Tensile Strength CD ≥(KN/m) | 25 | 30 | 40 | 60 | 80 | 100 | 125 | |

Typical strain at M.A.T.S. MD ≤(%) | 10.0 | |||||||

Typical strain at M.A.T.S. CD ≤(%) | 10.0 | |||||||

Tensile Strength at 2% Strain-MD ≥(KN/m) | 10 | 14 | 20 | 22 | 35 | 55 | 60 | |

Tensile Strength at 2% Strain-CD≥(KN/m) | 10 | 14 | 20 | 22 | 35 | 55 | 60 | |

Tensile Strength at 5% Strain-MD≥(KN/m) | 15 | 20 | 25 | 40 | 55 | 65 | 90 | |

Tensile Strength at 5% Strain-CD≥(KN/m) | 15 | 20 | 25 | 40 | 55 | 65 | 90 | |

Note: The specified Ultimate Tensile strength at 2% and 5%, can be adjusted to meet customized request. | ||||||||

Grid Structure | Welded geogrid | |||||||

Aperture Size | 50mm x 50mm (±10mm) | |||||||

Color | Black | |||||||

Roll Width | 3.9m/5.9m | |||||||

Roll Length | 50m | |||||||

Plastic Ultrasonic Welded Geogrid are warp knitted polypropylene materials welded geogrid,it use polypropylene as raw materials,through extruding to be high tensile strength rib belt ,then the belts warp knitted and welded by Ultrasonic welding machine to make it have high tensile strength in CD/MD direction. This products mainly used for Soil stabilization,road sub-base reinforcement, aggregates confinement and improving the performance of road anti-pressure ability.

Features:

Plastic Ultrasonic Welded Geogrid is a high-quality and reliable solution for all your geotechnical needs. Designed with utmost precision and manufactured using state-of-the-art technology, this geogrid offers exceptional performance and durability.

With its high tensile strength, our Plastic Ultrasonic Welded Geogrid can withstand heavy loads and provide excellent reinforcement to the soil. This feature ensures enhanced load distribution, preventing soil erosion and offering long-lasting stability to your projects.

Installation of our geogrid is both convenient and easy, saving you valuable time and effort. Its innovative design allows for seamless integration into various applications, making it suitable for a wide range of projects. Whether you are working on road construction, embankments, or retaining walls, our geogrid guarantees efficient and hassle-free installation.

Technical Properties Specification | ||||||||

Spec Items | GSZ25 | GSZ30 | GSZ40 | GSZ60 | GSZ80 | GSZ100 | GSZ125 | |

Minimum Average Tensile Strength MD ≥(KN/m) | 25 | 30 | 40 | 60 | 80 | 100 | 125 | |

Minimum Average Tensile Strength CD ≥(KN/m) | 25 | 30 | 40 | 60 | 80 | 100 | 125 | |

Typical strain at M.A.T.S. MD ≤(%) | 10.0 | |||||||

Typical strain at M.A.T.S. CD ≤(%) | 10.0 | |||||||

Tensile Strength at 2% Strain-MD ≥(KN/m) | 10 | 14 | 20 | 22 | 35 | 55 | 60 | |

Tensile Strength at 2% Strain-CD≥(KN/m) | 10 | 14 | 20 | 22 | 35 | 55 | 60 | |

Tensile Strength at 5% Strain-MD≥(KN/m) | 15 | 20 | 25 | 40 | 55 | 65 | 90 | |

Tensile Strength at 5% Strain-CD≥(KN/m) | 15 | 20 | 25 | 40 | 55 | 65 | 90 | |

Note: The specified Ultimate Tensile strength at 2% and 5%, can be adjusted to meet customized request. | ||||||||

Grid Structure | Welded geogrid | |||||||

Aperture Size | 50mm x 50mm (±10mm) | |||||||

Color | Black | |||||||

Roll Width | 3.9m/5.9m | |||||||

Roll Length | 50m | |||||||