close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

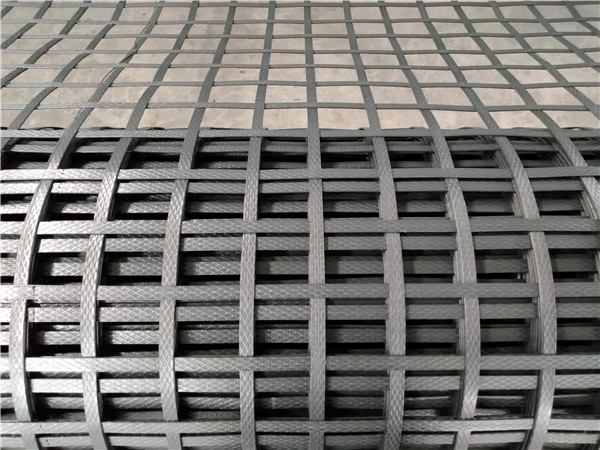

PP(POLYPROPYLENE) Welded Geogrid

POLYPROPYLENE (PP) WELDED GEOGRID

PP(POLYPROPYLENE) Welded Geogrid are warp knitted polypropylene materials welded geogrid,it use polypropylene as raw materials,through extruding to be high tensile strength rib belt ,then the belts warp knitted and welded by Ultrasonic welding machine to make it have high tensile strength in CD/MD direction. This products mainly used for Soil stabilization,road sub-base reinforcement, aggregates confinement and improving the performance of road anti-pressure ability.

Features:

With high tensile strength in longitudinal and transverse directions.

This structure can provide a chain system to provide more efficient bearing and spreading reinforce for the soft soil.

Can adapt to all kinds of environment soil and completely satisfy the use of tall retaining wall of high grade highway.

Benefits:

Distribution of loads and therefore reduction in stress concentration over the soil.

Increase in load distribution. (Bearing Capacity Increase)

Controls differential settlement.

Convenient and easy installation.

Efficiently improve the bearing capacity of soft road base,control the soil’s lateral movement.

Application:

Veneer reinforcement.

Reinforcement of granular road base.

Area stabilization.

Track-bed stabilization.

Load transfer platform.

Technical Properties Specification | ||||||||

Spec Items | GSZ25 | GSZ30 | GSZ40 | GSZ60 | GSZ80 | GSZ100 | GSZ125 | |

Minimum Average Tensile Strength MD ≥(KN/m) | 25 | 30 | 40 | 60 | 80 | 100 | 125 | |

Minimum Average Tensile Strength CD ≥(KN/m) | 25 | 30 | 40 | 60 | 80 | 100 | 125 | |

Typical strain at M.A.T.S. MD ≤(%) | 10.0 | |||||||

Typical strain at M.A.T.S. CD ≤(%) | 10.0 | |||||||

Tensile Strength at 2% Strain-MD ≥(KN/m) | 10 | 14 | 20 | 22 | 35 | 55 | 60 | |

Tensile Strength at 2% Strain-CD≥(KN/m) | 10 | 14 | 20 | 22 | 35 | 55 | 60 | |

Tensile Strength at 5% Strain-MD≥(KN/m) | 15 | 20 | 25 | 40 | 55 | 65 | 90 | |

Tensile Strength at 5% Strain-CD≥(KN/m) | 15 | 20 | 25 | 40 | 55 | 65 | 90 | |

Note: The specified Ultimate Tensile strength at 2% and 5%, can be adjusted to meet customized request. | ||||||||

Grid Structure | Welded geogrid | |||||||

Aperture Size | 50mm x 50mm (±10mm) | |||||||

Color | Black | |||||||

Roll Width | 3.9m/5.9m | |||||||

Roll Length | 50m | |||||||

Plant Workshop

Storage

Delivery

Certificates

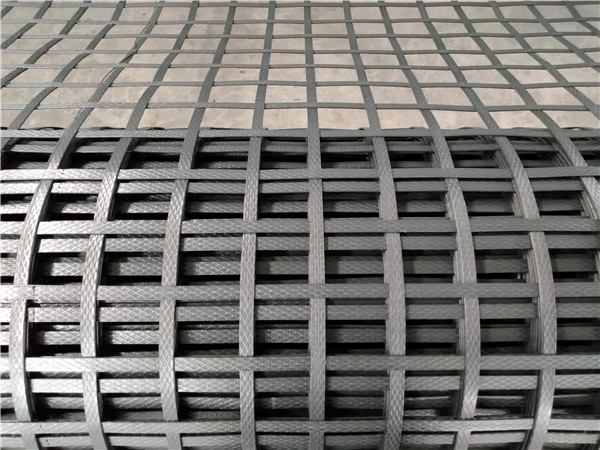

POLYPROPYLENE (PP) WELDED GEOGRID

PP(POLYPROPYLENE) Welded Geogrid are warp knitted polypropylene materials welded geogrid,it use polypropylene as raw materials,through extruding to be high tensile strength rib belt ,then the belts warp knitted and welded by Ultrasonic welding machine to make it have high tensile strength in CD/MD direction. This products mainly used for Soil stabilization,road sub-base reinforcement, aggregates confinement and improving the performance of road anti-pressure ability.

Features:

With high tensile strength in longitudinal and transverse directions.

This structure can provide a chain system to provide more efficient bearing and spreading reinforce for the soft soil.

Can adapt to all kinds of environment soil and completely satisfy the use of tall retaining wall of high grade highway.

Benefits:

Distribution of loads and therefore reduction in stress concentration over the soil.

Increase in load distribution. (Bearing Capacity Increase)

Controls differential settlement.

Convenient and easy installation.

Efficiently improve the bearing capacity of soft road base,control the soil’s lateral movement.

Application:

Veneer reinforcement.

Reinforcement of granular road base.

Area stabilization.

Track-bed stabilization.

Load transfer platform.

Technical Properties Specification | ||||||||

Spec Items | GSZ25 | GSZ30 | GSZ40 | GSZ60 | GSZ80 | GSZ100 | GSZ125 | |

Minimum Average Tensile Strength MD ≥(KN/m) | 25 | 30 | 40 | 60 | 80 | 100 | 125 | |

Minimum Average Tensile Strength CD ≥(KN/m) | 25 | 30 | 40 | 60 | 80 | 100 | 125 | |

Typical strain at M.A.T.S. MD ≤(%) | 10.0 | |||||||

Typical strain at M.A.T.S. CD ≤(%) | 10.0 | |||||||

Tensile Strength at 2% Strain-MD ≥(KN/m) | 10 | 14 | 20 | 22 | 35 | 55 | 60 | |

Tensile Strength at 2% Strain-CD≥(KN/m) | 10 | 14 | 20 | 22 | 35 | 55 | 60 | |

Tensile Strength at 5% Strain-MD≥(KN/m) | 15 | 20 | 25 | 40 | 55 | 65 | 90 | |

Tensile Strength at 5% Strain-CD≥(KN/m) | 15 | 20 | 25 | 40 | 55 | 65 | 90 | |

Note: The specified Ultimate Tensile strength at 2% and 5%, can be adjusted to meet customized request. | ||||||||

Grid Structure | Welded geogrid | |||||||

Aperture Size | 50mm x 50mm (±10mm) | |||||||

Color | Black | |||||||

Roll Width | 3.9m/5.9m | |||||||

Roll Length | 50m | |||||||

Plant Workshop

Storage

Delivery

Certificates